Module Group Overview

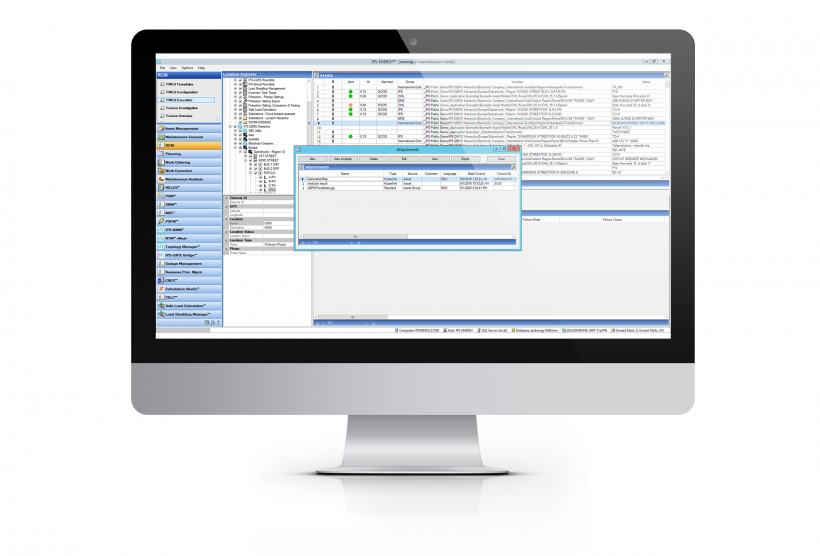

IPS® Reliability Centered Maintenance

The purpose of IPS®RCM is to facilitate optimizing the maintenance plan for technical equipment, thereby reducing the failure rate and to preserving system functions. System functions are the core of this maintenance concept, which takes a calculated level of risk into account to ensure efficient and cost-conscious operation.

IPS®RCM module ensures cost-effective and reliable operations of your technological assets. This is accomplished by applying maintenance strategies that focus on the most essential functions of the equipment, and their position in the grid.

IPS®RCM is used to define an approach for optimized maintenance plans by focusing on the following aspects:

- Failure Modes (how the equipment can fail),

- Failure Cause (the cause of the failure, including root cause),

- Failure Effect (including severity, local, overall),

- Detection Control (how to detect failure before it happens),

- Prevention Controls (how to prevent the failure),

- IEC 60300-3-11 (initiation and planning) and

- And many more…

Module Overview

The ability to track FMEA (Failure Modes and Effects Analysis) is an essential element of IPS®RCM. This allows the client to reduce the probability of system component failures or avoid them altogether. FMEA is a tool that helps users analyze potential failure modes.

IPS-Reliability Centered Maintenance consists of the following modules:

- FMEA Templates ,

- FMEA Configuration ,

- FMEA Execution,

- Failure Investigation ,

- Failure Overview and

- Failure Type Library.

One of the core functionalities of the IPS®RCM module is the prediction of failure modes. With the calculation of different factors, including the risk of failure and effects, the priority of maintenance actions can be optimized.